EXPLORING HAWAII OIL – Basic Components of Lubricating Oil

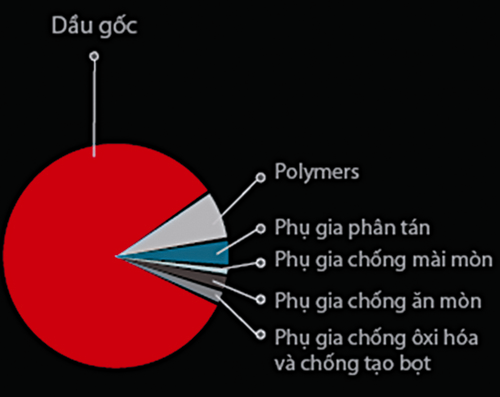

The fundamental composition of most lubricating oils is predominantly base oil, constituting 75-80% of the overall weight. Despite being a minor component, additives play a crucial role in determining the quality distinctions among lubricants.

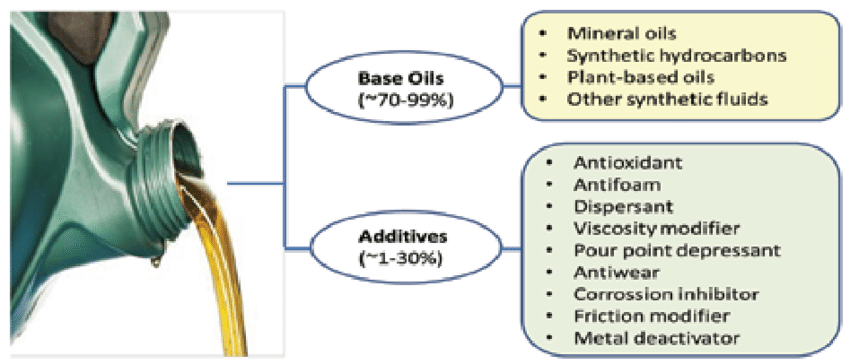

Designed for lubricating internal combustion engines, authentic lubricating oil is a blend of base oil and various additives. Base oil, derived from refined and synthetically treated oil through physical and chemical processes, forms the core of the mixture.

Thành phần cơ bản của dầu nhớt

Classified based on the composition of the base oil, lubricating oils fall into three categories: mineral oil (mainly comprising mineral base oil), synthetic oil (the highest-grade due to its pure composition and stable high viscosity, enhancing engine protection), and semi-synthetic oil (a fusion of mineral and synthetic oil).

Additives, accounting for approximately 20-25%, encompass polymers (present only in multi-grade oils) to enable lubricating oil functionality under diverse temperature conditions. Additionally, detergent and dispersant additives serve to cleanse the engine, anti-wear additives protect against mechanical friction, and anti-corrosion additives shield from chemical corrosion. Oxidation inhibitors and anti-foaming agents prevent internal engine oxidation and maintain stable lubricant properties by thwarting oxidation-related issues like sludge formation and thickening.

Effective engine protection through lubricating oil is contingent on meeting two key criteria: uniform oil distribution across all friction surfaces and engine temperatures surpassing 70 degrees Celsius. During operation, the requisite amount of lubricating oil is consistently pumped into the engine, with engine temperatures typically exceeding the minimum threshold. However, this is not the case during the engine startup and warm-up period.

Lubricating oil serves the pivotal functions of lubrication, cooling, and cleaning, preventing direct metal-to-metal contact on friction surfaces and safeguarding the engine from debris generated during operation.

When the engine is inactive, lubricating oil drains from vital engine parts and settles in the oil pan. Upon vehicle startup, the initial oil quantity may be insufficient to shield most engine components, especially those distant from the oil pump. It takes up to 20 minutes for the oil in the pan to be pumped and evenly distributed over friction surfaces. This is also the critical window when the lubricating oil has not yet reached the optimal temperature for the full effectiveness of anti-wear additives. Research experiments have highlighted that this brief 20-minute period contributes to up to 75% of the wear experienced by the engine. Consequently, the startup phase poses the highest risk of wear and demands maximum protective measures.

In addition to lubricating oil products such as HAWAII HYDRAULIC ISO, HAWAII HYDRAULIC VG, and HAWAII HYDRAULIC AW, Hawaii Oil also provides a range of high-quality products to meet diverse customer needs.

Each product from Hawaii Oil is crafted with advanced technology and meets high-quality standards to ensure stable performance and optimal protection for the essential components of vehicles and machinery.